Korean researchers have used thermal and moist gravity separation (WGS) to separate EVA from reclaimed silicon powder in end-of-life PV modules with “minimal” chemical utilization. The proposed approach offers silicon powder that could possibly be reused as a uncooked materials for upcycling into silicon nitride, silicon oxide, or silicon carbide.

Emiliano Bellini

Schematic of the PV recycling course of

Schematic of the PV recycling course of

” data-medium-file=”https://www.pv-magazine.com/wp-content/uploads/2024/10/thumbnail_PV-recycling-process-600×287.png” data-large-file=”https://www.pv-magazine.com/wp-content/uploads/2024/10/thumbnail_PV-recycling-process-1200×575.png” tabindex=”0″ position=”button”>

Schematic of the PV recycling course of

Picture: Gyeongsang Nationwide College

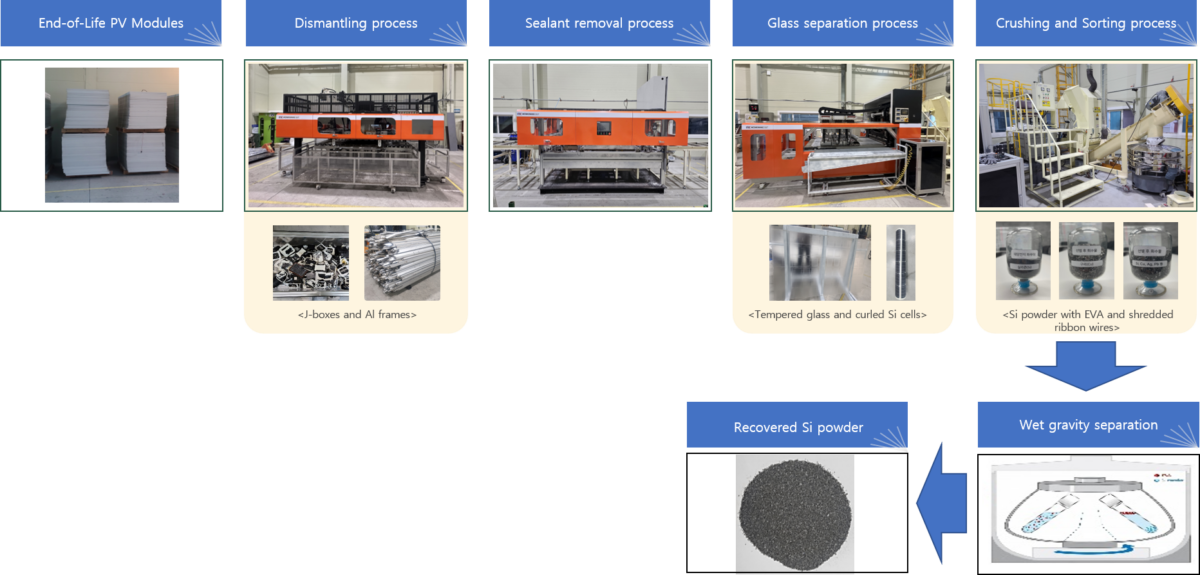

Researchers on the Gyeongsang Nationwide College Jinju in South Korea have developed a brand new technique for separating ethylene vinyl acetate (EVA) encapsulant from recycled silicon energy in end-of-life (EoL) photo voltaic panels.

In frequent mechanical recycling processes, EVA is blended after the crushing or grinding, whereas chemical and delamination strategies are usually time-consuming or create harmful waste merchandise. The brand new course of makes use of thermal and moist gravity separation (WGS) to separate EVA from reclaimed Si powder with “minimal.” chemical utilization, in keeping with the researchers.

The moist gravity separation course of makes use of an aqueous sodium chloride (NaCl) answer that exploits the gravity distinction between silicon and EVA and the WGS course of makes use of particular gravities of the 2 supplies to facilitate their centrifugation. “All recycling processes had been carried out within the industrial facility apart from moist gravity separation to take away ethylene vinyl acetate (EVA) encapsulant,” the analysis’s corresponding creator, Jongsung Park, advised pv journal.

The complete course of begins with dismantling the module aluminum body and eradicating the sealant. Then, a grinding course of removes the backsheet and a heating course of separates the remaining layers. The next step consists of a shredding course of to pick photo voltaic cells encapsulated in EVA, which is adopted by a sorting course of primarily based on particle dimension variations of shredded supplies. As well as, small particle-size powder-type photo voltaic cells and metals are separated and a thermal course of eliminates the EVA contained in silicon powder.

“The thermal course of at 550 C successfully eliminated all polymer elements, particularly EVA, from the reclaimed silicon powder, as confirmed by varied analytical strategies equivalent to TGA, FT-IR, SEM, and EDS,” the group defined. “Whereas efficient, the thermal course of has notable drawbacks, together with excessive power consumption and important carbon dioxide emissions, making it much less environmentally pleasant than the WGS.”

Additional evaluation confirmed the efficient removing of EVA and different polymers. “The recycling of EoL PV modules was carried out in a industrial facility and an environmentally pleasant course of was used to get better high-purity silicon,” Park defined. “We recovered the silicon in powder type and won’t use it for photo voltaic cell manufacturing once more, however as a uncooked materials for upcycling into silicon nitride (SiNx), silicon oxide (SiOx), or silicon carbide (SiC).”

The scientists introduced the novel approach within the research “Growth of eco-friendly pretreatment processes for high-purity silicon restoration from end-of-life photovoltaic modules,” which was just lately printed within the Royal Society of Chemistry.

This content material is protected by copyright and is probably not reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.

In style content material