A brand new 3D-printed design might make an integral a part of cooling programs like air conditioners or fridges smaller and extra environment friendly, in accordance with new analysis.

Warmth exchangers are gadgets that whisk away warmth, and so they’re in all places—utilized in information facilities, ships, factories, and buildings. The intention is to cross as a lot warmth as attainable from one facet of the system to the opposite. Most use one of some normal designs which have traditionally been best and least expensive to make.

“Warmth exchangers are on the heart of the economic financial system. They’re an important a part of each machine and each system that strikes power,” says William King, a professor on the College of Illinois Urbana-Champaign and one of many authors of the brand new research. Current designs are likely to favor straight traces, proper angles, and spherical tubes, he provides.

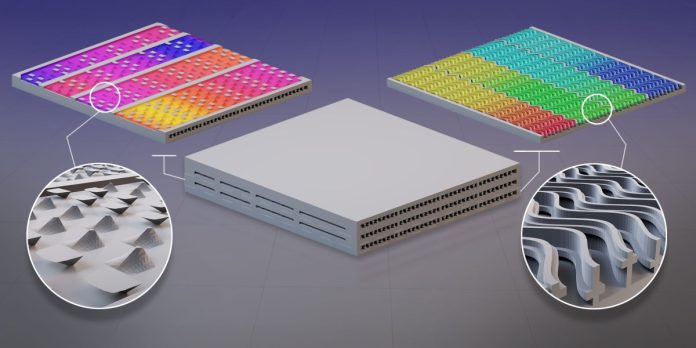

King and his colleagues used 3D printing to design a warmth exchanger that features options to optimize warmth motion, like wavy partitions and pyramid-shaped bumps, which wouldn’t be attainable to make utilizing conventional manufacturing strategies.

The group had got down to design a system primarily based on a standard refrigerant known as R-134a, which is usually utilized in gadgets like air conditioners and fridges. When chilly water lowers the temperature of the refrigerant, it adjustments from a gasoline to a liquid on its path by means of the system. That liquid refrigerant can then go on to different elements of the cooling system, the place it’s used to decrease the temperature of something from a room to a rack of servers.

One of the simplest ways to chill the refrigerant tends to contain constructing very skinny partitions between the 2 sides of the system and maximizing the quantity of contact that the water and the refrigerant make with these partitions. (Take into consideration how a lot colder you’d get carrying a skinny T-shirt and pants and mendacity down on ice than merely touching it together with your gloved arms.)

To design the very best warmth exchanger, researchers used simulations and developed machine-learning fashions to assist predict the efficiency of various designs underneath completely different situations. After 36,000 simulations, the researchers landed on the one they determined to develop.

Among the many key elements: small fins that jut out on the facet of the system that touches the water, rising the floor space to maximise warmth switch. The group additionally designed wavy passageways for the water to cross by means of—as soon as once more serving to to maximise floor space. Simulations helped the researchers determine precisely how curvy the passages needs to be and the place exactly to position the fins.

On the facet of the gadgets the place the refrigerant passes by means of, the design consists of small pyramid-shaped bumps alongside the partitions. These not solely maximize the world for cooling but in addition assist combine the refrigerant because it passes by means of and forestall liquid from coating the wall (which might decelerate the warmth switch).

After selecting a design, the researchers used a 3D-printing approach known as direct steel laser sintering, by which lasers soften and fuse collectively a steel powder (on this case, an aluminum alloy), layer by layer.

In testing, the researchers discovered that the warmth exchanger created with this system was in a position to calm down the refrigerant extra effectively than different designs. The brand new system was in a position to obtain an influence density of over six megawatts per meter cubed—outperforming one frequent conventional design, the shell-tube configuration, by between 30% and 50% with the identical pumping energy. The system’s energy density was much like that of brazed plate warmth exchangers, one other frequent design in trade.

General, this system doesn’t dramatically outperform the state-of-the-art know-how, however the strategy of utilizing modeling and 3D printing to provide new warmth exchanger designs is promising, says Dennis Nasuta, director of analysis and improvement at Optimized Thermal Programs, a consulting agency that works with corporations within the HVAC trade on design and analysis. “It’s value exploring, and I don’t suppose that we all know but the place we will push it,” Nasuta says.

One problem is that right this moment, additive manufacturing strategies reminiscent of laser sintering are gradual and costly in contrast with conventional manufacturing; they wouldn’t be economical or possible to depend on for all our shopper cooling gadgets, he says. For now, one of these strategy may very well be most helpful in area of interest purposes like aerospace and high-end automotives, which might extra doubtless bear the price, he provides.

This explicit research was funded by the US Workplace of Naval Analysis. Subsequent-generation ships have extra electronics aboard than ever, and there’s a rising want for compact and environment friendly programs to take care of all that further warmth, says Nenad Miljkovic, one of many authors of the research.

Vitality demand for cooling buildings alone is about to double between now and 2050, and new designs might assist effectively meet the large demand forecast for the approaching many years. However challenges together with manufacturing prices would must be overcome to assist improvements just like the one designed by King and his group make a dent in actual gadgets.

One other barrier to adopting these new strategies, Nasuta says, is that present requirements don’t demand extra effectivity. Different applied sciences exist already that might assist make our gadgets extra environment friendly, however they’re not used for a similar purpose.

It is going to take time for brand spanking new manufacturing strategies, together with 3D printing, to trickle into our gadgets, Natsua provides: “This isn’t going to be in your AC subsequent yr.”